-

Basic knowledge of FPC circuit board2021-03-08

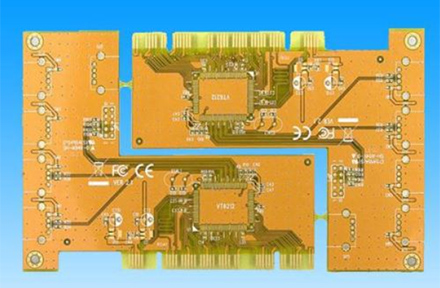

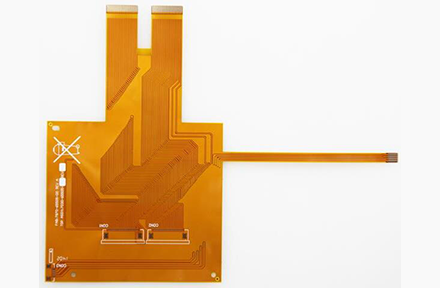

Basic knowledge of FPC circuit board2021-03-08With the continuous increase in the yield ratio of flexible PCBs and the application and promotion of rigid-flex PCBs, it is now more common to add soft, rigid or rigid-flex when talking about PCBs, and say that it is a few-layer FPC. Generally, an FPC made of a soft insulating substrate is called a soft FPC or a flexible FPC, and a rigid-flex composite PCB is called a rigid-flex PCB. It meets the needs of today's electronic products for high density, high reliability, small scale, and lightweight progress. It also satisfies the strict economic requirements and the needs of market and technology competition.

-

Fpc flexible circuit board test method and standard2021-03-08

Fpc flexible circuit board test method and standard2021-03-08FPC flexible circuit board, English called Flexible Printed Circuit, commonly known as "soft board", also called flexible circuit board, is a kind of flexible insulating substrate made of polyimide or polyester film with high reliability. A stunning flexible printed circuit board. It has a unique place with high degree of wiring density, light weight, thin thickness, and good bendability. Flexible printed circuit boards are also divided into single-sided, double-sided and multi-layer boards.

-

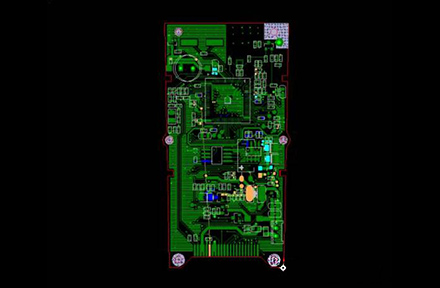

Interpretation of four-layer PCB circuit board stack design scheme2021-03-08

Interpretation of four-layer PCB circuit board stack design scheme2021-03-08When imagining a four-layer PCB circuit board, how to imagine that the stack is normal?

In practice, there can be three plans.

Plan one, 1 power layer, 1 floor, and 2 signal layers. Discrimination is displayed like this: TOP (signal layer), L2 (floor), L3 (power layer), BOT (signal layer).

Plan two, 1 power layer, 1 floor, and 2 signal layers. The identification is displayed like this: TOP (power layer), L2 (signal layer), L3 (signal layer), BOT (floor).

Plan three, 1 power layer, 1 floor, and 2 signal layers. Discrimination is displayed like this: TO -

What are the common rules for PCB wiring?2021-03-08

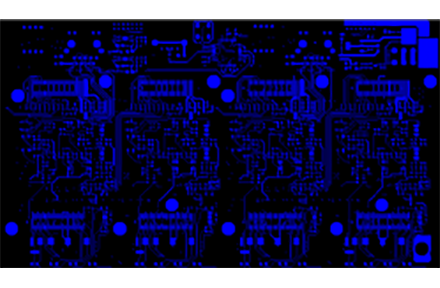

What are the common rules for PCB wiring?2021-03-08PCB wiring refers to paving and repairing electrical signal roads to connect various components. In the PCB preset, wiring is a key step to complete the product preset.

What are the common rules for PCB circuit board wiring -

PCB assembly quality and reliability control of electroless nickel-palladium-gold plating2021-03-08

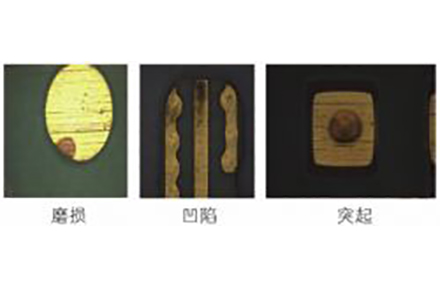

PCB assembly quality and reliability control of electroless nickel-palladium-gold plating2021-03-08The PCB electroless nickel-palladium-gold (ENEPIG) coating can meet the requirements of surface mounting, conductive adhesive bonding, gold wire/aluminum wire bonding and other process requirements at the same time, and the application of micro-assembly technology is widely used day by day. In the micro-assembly process, the process quality problems of the chemical nickel-palladium-gold PCB in terms of gold wire bonding and solder joint reliability were discussed, and the mechanism and reasons affecting the process reliability were analyzed, and the process reliability control was proposed. The way to deal with it.

-

Introduce common printed circuit board standards2021-03-08

Introduce common printed circuit board standards2021-03-08There are many standards in the circuit board industry, and the commonly used printed circuit board standards are as follows:

1) IPC-ESD-2020: A joint standard for the development of electrostatic discharge control procedures. Covers the presupposition, establishment, successful realization and protection necessary for electrostatic discharge control procedures. Based on the historical experience of certain military groups and economic activity groups, provide guidance for the sensitive period of electrostatic discharge disposal and best care. -

The popularity of new energy vehicles will drive the increase in the PCB market2018-11-08

The popularity of new energy vehicles will drive the increase in the PCB market2018-11-08Traditional cars are not highly electronic at this stage, the demand for PCBs is small, and the value of PCBs is relatively low. PCB accounts for about 2% of the total cost of electronic devices. The average PCB consumption per car is about 1 square meter, worth 60 US dollars, and the consumption of high-end models is 2-3 square meters, worth about 120-130 US dollars. Among the electronic components of traditional automobiles, the power system requires the most PCB, with a share of 32%, mainly including engine control units, starters, generators, transmission control devices, fuel injection, power steering systems, etc.; body electronic systems 25%, main

-

Taiwanese and Japanese PCB industries actively invest in 5G applications2018-11-08

Taiwanese and Japanese PCB industries actively invest in 5G applications2018-11-08The Trump administration in the United States has focused on ZTE and Huawei in mainland China, and conducted technology export controls and investigations. They were interpreted as restricting the development of 5G communications in mainland China, which has been advanced, and its importance is obvious. The Taiwanese PCB industry is also actively investing in 5G applications. , Nissho Nittobo and Hitachi Chemical Chengdu came to Taiwan to take a foot. The focus of Japanese businessmen’s investment in Taiwan lies in the PCB upstream raw materials including CCL and fiberglass cloth industries, and they are also rushing to attack the high-frequency, high-speed, and signal but lost PCB raw materials required for the upgrade of the soft and hard board process, including Hitachi Chemical (Hitachi Chemical) announced that it will invest

-

PCB design technical challenges-how to shorten the timeline and optimize design flexibility2018-11-08

PCB design technical challenges-how to shorten the timeline and optimize design flexibility2018-11-08As smart devices dominate, people are beginning to enter smart homes, smart cities, smart computing, and the Internet of Things. PCBs require more and more functions. For example, processors, sensing, connections, power management, etc., are all PCB design establishments. Under technical challenges and a race against time, shortening design time, optimizing design flexibility and high degree of customization have become the unanimous goals of developers. New design concept-With GreenPAK, PCB design is even more powerful. Focusing on this common pursuit, Dialog especially provides a new editable mixed signal IC product (ConfigurableM

-

PCB design process-from schematic to PCB2018-11-08

PCB design process-from schematic to PCB2018-11-08Many friends are interested in the PCB design process. Next, Shenzhen Honglijie will introduce the design process from schematic to PCB. 1. Establish component parameters from schematic to PCB design flow -> input principle netlist -> design parameter settings -> manual layout -> manual wiring -> verify design -> review -> CAM output. 2. Parameter setting The distance between adjacent wires must be able to meet electrical safety requirements, and in order to facilitate operation and production, the distance should be as wide as possible. The minimum spacing must be at least suitable for the voltage tolerated. When the wiring density is low, the spacing of the signal lines can be increased appropriately.

Service Hotline:

Email:lhdpcb@vip.163.com

Address:No. 26, Meiyuan 3rd Road, Intercontinental Industrial Park, Luoyang Town, Boluo County, Huizhou

Copyright ©Huizhou Linghangda Technology Co., Ltd. All Rights Reserved 粤ICP备18145577号

Power by: www.300.cn

0752-6260118

0752-6260118

QQ

QQ