PCB assembly quality and reliability control of electroless nickel-palladium-gold plating

- Categories:Company News

- Author:

- Origin:

- Time of issue:2021-03-08

- Views:

(Summary description)The PCB electroless nickel-palladium-gold (ENEPIG) coating can meet the requirements of surface mounting, conductive adhesive bonding, gold wire/aluminum wire bonding and other process requirements at the same time, and the application of micro-assembly technology is widely used day by day. In the micro-assembly process, the process quality problems of the chemical nickel-palladium-gold PCB in terms of gold wire bonding and solder joint reliability were discussed, and the mechanism and reasons affecting the process reliability were analyzed, and the process reliability control was proposed. The way to deal with it.

PCB assembly quality and reliability control of electroless nickel-palladium-gold plating

(Summary description)The PCB electroless nickel-palladium-gold (ENEPIG) coating can meet the requirements of surface mounting, conductive adhesive bonding, gold wire/aluminum wire bonding and other process requirements at the same time, and the application of micro-assembly technology is widely used day by day. In the micro-assembly process, the process quality problems of the chemical nickel-palladium-gold PCB in terms of gold wire bonding and solder joint reliability were discussed, and the mechanism and reasons affecting the process reliability were analyzed, and the process reliability control was proposed. The way to deal with it.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2021-03-08

- Views:

The PCB electroless nickel-palladium-gold (ENEPIG) coating can meet the requirements of surface mounting, conductive adhesive bonding, gold wire/aluminum wire bonding and other process requirements at the same time, and the application of micro-assembly technology is widely used day by day. In the micro-assembly process, the process quality problems of the chemical nickel-palladium-gold PCB in terms of gold wire bonding and solder joint reliability were discussed, and the mechanism and reasons affecting the process reliability were analyzed, and the process reliability control was proposed. The way to deal with it.

The PCB electroless nickel-palladium-gold (ENEPIG) coating can satisfy the surface mounting, conductive adhesive bonding and gold/aluminum wire bonding process at the same time. MiladG, Lin Jindu and others have given a high reputation for the scene before the application of electroless nickel-palladium-gold. A thin layer of palladium is added between the nickel and the gold to prevent the gold from destroying the nickel in the gold immersion process and completely avoid the "black pad" phenomenon. The gold layer of this process is very thin (usually less than 0.1 μm). When solder reflow is used, there is no formation of AuSn4 brittle intermetallic compounds, and there is no risk of gold embrittlement. There is no need to electroplating thick gold process lines, the process is simplified, and the performance of the microwave circuit is guaranteed. Compared with gold, the price of palladium is lower, and the thickness of palladium and gold are very thin. This process is very competitive in terms of cost control. PENGSP et al. researched that EPENIG can form a solid and reliable solder joint with the lead-free solder SAC305, and the plating layer satisfies the Rohs requirements.

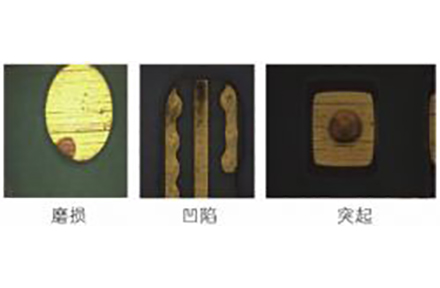

The chemical nickel-palladium-gold process has been mature overseas and has been widely used. In recent years, the process has been gradually promoted in domestic policies. The domestic research on the process is carried out layer by layer, covering process analysis, application research and quality control. Because the process control is complicated, if the coating parameter control system is inappropriate or the assembly process parameters are uncertain, it will easily affect the quality and reliability of the production, mainly showing that the gold wire bondability and the welding of BGA parts are reliable. Sexual issues.

Scan the QR code to read on your phone

-

Basic knowledge of FPC circuit board

With the continuous increase in the yield ratio of flexible PCBs and the application and promotion of rigid-flex PCBs, it is now more common to add soft, rigid or rigid-flex when talking about PCBs, and say that it is a few-layer FPC. Generally, an FPC made of a soft insulating substrate is called a soft FPC or a flexible FPC, and a rigid-flex composite PCB is called a rigid-flex PCB. It meets the needs of today's electronic products for high density, high reliability, small scale, and lightweight progress. It also satisfies the strict economic requirements and the needs of market and technology competition. - Fpc flexible circuit board test method and standard 03-08

- Interpretation of four-layer PCB circuit board stack design scheme 03-08

- What are the common rules for PCB wiring? 03-08

- PCB assembly quality and reliability control of electroless nickel-palladium-gold plating 03-08

Service Hotline:

Email:lhdpcb@vip.163.com

Address:No. 26, Meiyuan 3rd Road, Intercontinental Industrial Park, Luoyang Town, Boluo County, Huizhou

Copyright ©Huizhou Linghangda Technology Co., Ltd. All Rights Reserved 粤ICP备18145577号

Power by: www.300.cn

0752-6260118

0752-6260118

QQ

QQ